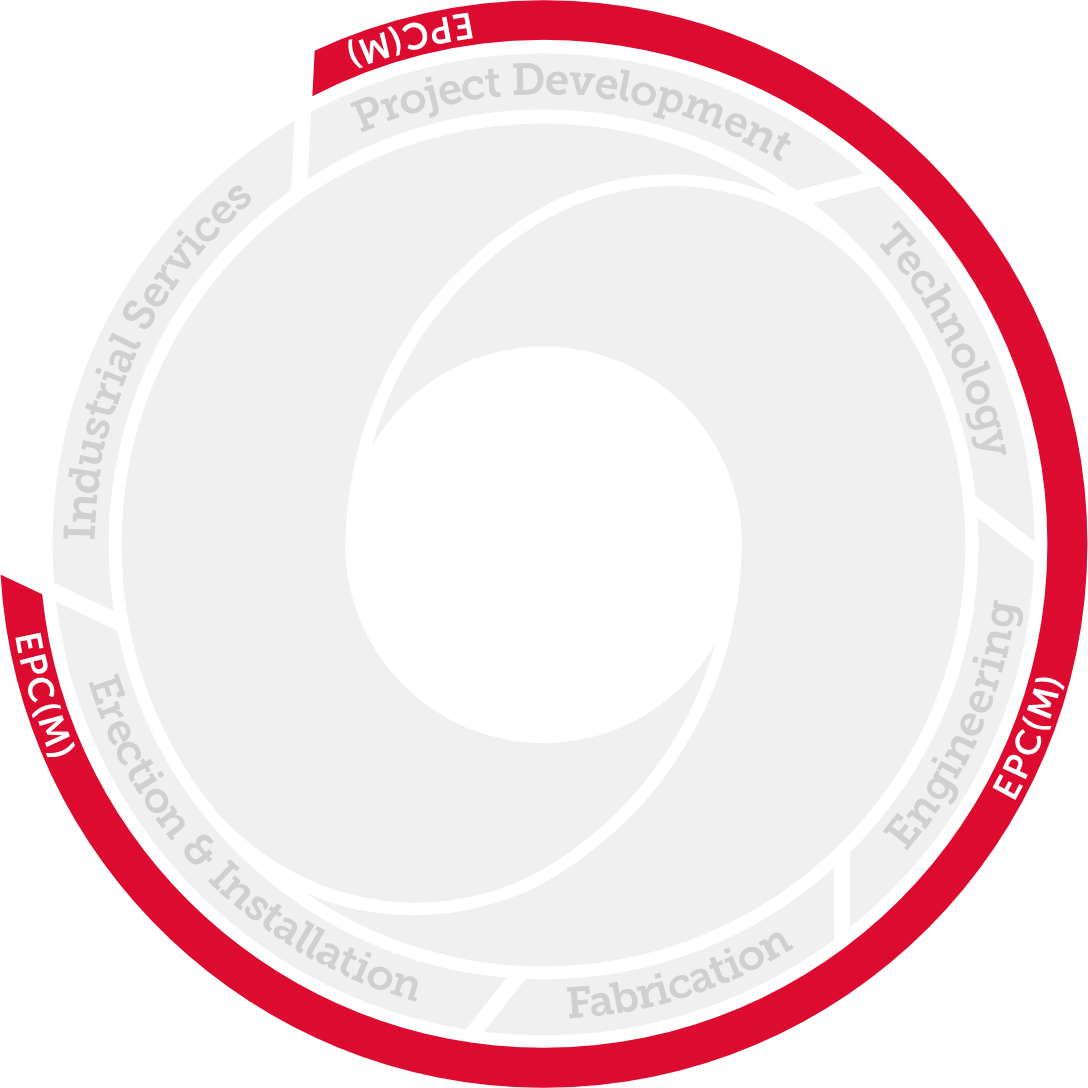

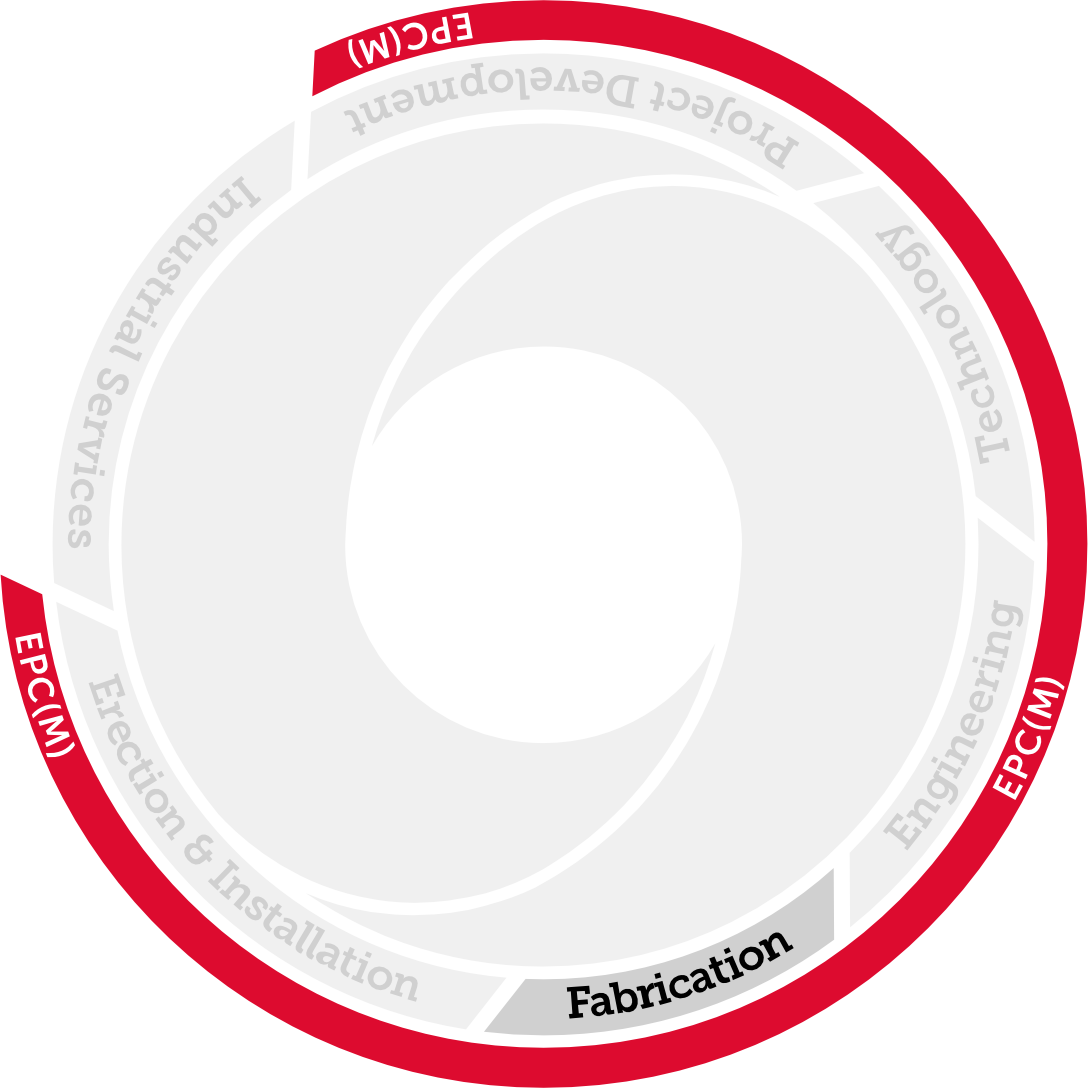

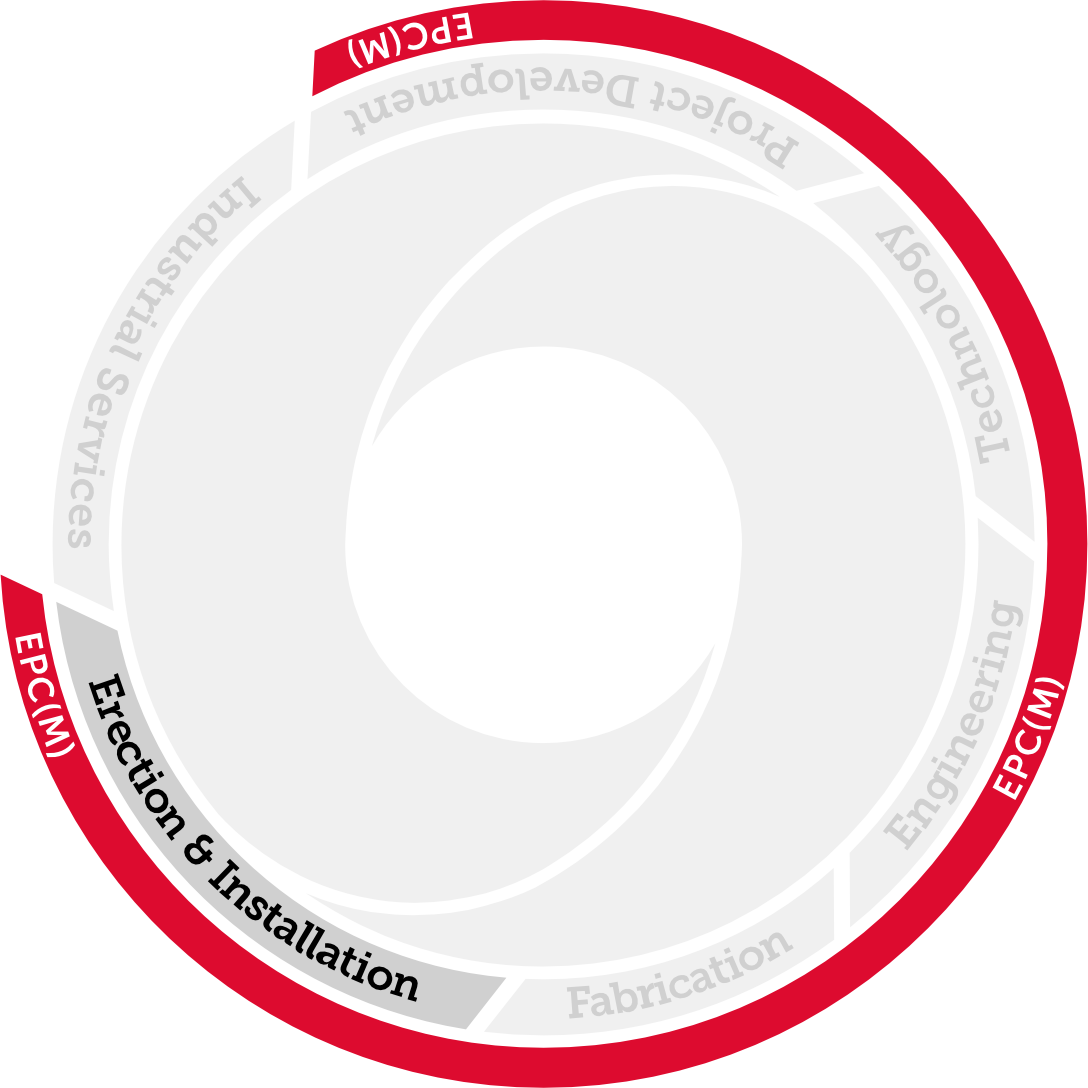

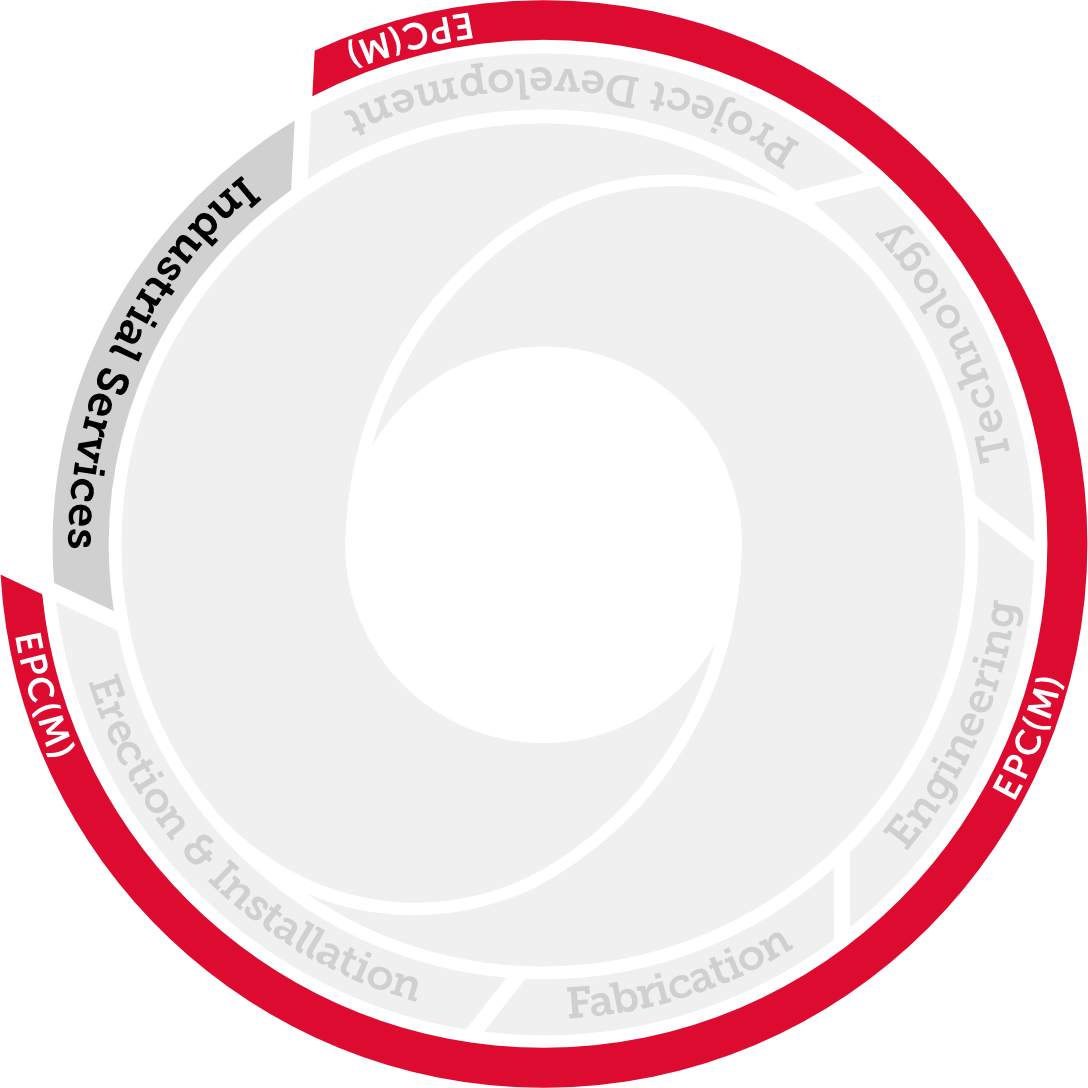

Our Services throughout the 360° Lifecycle of Your Industrial Plant

Utmost Efficiency in Energy Recovery and Waste Utilisation

Oschatz Global is the leading specialist for thermal treatment technologies, energy recovery and waste utilisation in industrial plants. Waste heat recovery systems for converting industrial waste heat into steam and other forms of energy are at the heart of our portfolio. Innovative know-how and patented proprietary technologies as well as Christof Industries’ 360° portfolio in industrial plant construction mean that Oschatz Global has a unique market position in the fields of ferrous and non-ferrous metallurgy, as well as chemical, energy and power plant technology. Our technologies are a key element in Christof Industries’ solutions for a modern, future-oriented circular economy.

Project Development

Innovation that Builds on Tried-and-Tested Solutions. To date, some 650 Oschatz Global waste heat recovery boilers have been successfully implemented for the iron and steel industry, non-ferrous metallurgy as well as for the chemical industry. Our strengths: innovative solutions that build on decades of experience, the most demanding quality standards, technical perfection and bespoke solutions for the highest possible levels efficiency and profitability.

- Industrial Consulting Services

- Front-End-Loading (FEL) Services

- Concept Studies

- Project Development

Technology

Industrial Pioneer and Leading Technology Partner. From an original focus on waste heat boilers, the core principle “steam from waste heat” has been refined over a period of more than 170 years, then customised and perfected for a variety of branches. The products that Oschatz Global provides range from ammonia incineration reactors for nitric acid production through to coolers for steelworks and production plants for non-ferrous metallurgical processes. Since the 1980s, this technology has also been successfully implemented in power plants for incinerating waste, biomass, and residues from chemical and production plants. As part of the Christof Industries group of companies, Oschatz Global is now one of the world’s leading technology companies in these fields. We employ our own patented technologies in line with the specific requirements of each plant project, which guarantees our customers superior tailor-made solutions.

- Waste-to-Energy/EBS Plants

- Incineration Plants for Liquid and Gaseous Residues/Waste Flows

- Biomass Power Plants

- Waste Heat Facilities for Process Technologies

- Process Gas Coolers

Engineering

Technical Perfection in Every Detail. Every facility is unique. Be they waste gas cooling facilities in metallurgy, components for the chemical industry or turn-key power plants for deriving thermal energy from biomass or residues: every facility is planned individually and tailored to meet our customers’ exact requirements. Oschatz Global demonstrates the value of know-how derived from decades of experience and a passion for innovation: from the project planning stage through to the most demanding basic and detail engineering – our engineers develop innovative, bespoke solutions that draw on tried-and-tested Oschatz Global technologies (“from chute to stack”).

- Conceptional Facility Planning

- Basic Engineering/FEED Services

- Detail Engineering

Fabrication

Cutting-Edge Production Facilities for Boiler Components and Spare Parts. Production facility with cutting-edge capabilities in China, coupled with our experts’ know-how, guarantee that our customers receive technical perfection with clear advantages in terms of time and cost for all types of fabrication and pre-assembly. Our core fabrication services for greenfield/brownfield facilities covers the fabrication of technological components and systems such as waste heat boilers, boiler systems, cooling stacks, skirts and cleaning technologies.

- Fabrication of Mechanical, Electrical and Automation Systems, Components and Spare Parts

- Pre-assembly of Technological Components

Erection & Installation

A One-Stop-Shop for Efficiency. Our broad range of services gives us the ability to respond in detail to the exact requirements of a given industrial plant project – from assembly through to start-up. The result: processes that are speedy, practical, and value for money, and which are a perfect fit for the specifications of the project in question.

- Construction Site Management and Supervision

- Interdisciplinary Facility Installation

- Plant Construction, Installation and Commissioning

- Personnel and User Training

Industrial Services

Optimisation of Life Cycle Costs. As part of the Christof Industries group of companies, Oschatz Global benefits from the competence and manpower of Industrial Service Teams at work across the globe. We focus on forward-looking industrial services that have a clear goal: ensuring the productivity and longevity of plants while increasing operating efficiency. Our range of services covers all elements of plant maintenance. This includes emergency response services, to ensure the quickest possible restoration of plant availability, the fabrication of all technological systems and components in our portfolio as well as the production, repair and replacement of parts and components.

- Plant Reconstructions, Upgrades and Modernisations

- Maintenance, Conversion and Upgrading of Facilities and Components

- Plant De-bottlenecking & Optimisation

- Spare Parts, Repair and Replacement of Components

We have served domestic and international markets from our Nanjing facility for 20 years with a fantastic performance record. We focus on providing our industrial partners with innovative engineering solutions that synergise with industrial value chains. Such results would not be possible without having HSEQ as an absolutely fundamental part in everything we do. With our sustainable economic growth value

we continue delivering our comparative advantage as a reliable partner for your thermal system.

Keyi (Larry) Yang, CSO, General Manager

Unwavering dedication to fostering strong relationships with stakeholders, along with our proactive approach, has propelled us to the forefront of the global technology and quality landscape. We are committed to environmental protection and strive for the highest sustainability standards. Our distinctive and vibrant entrepreneurial spirit and culture have

earned us recognition and set us apart in the industry.

Liwei (Vivian) Wang, CFO

Our team is dedicated to thriving in a fast-paced environment and committed to continuous self-improvement. With unique skills and experience, each individual embodies a strong spirit of craftsmanship, continually striving for improvement to deliver exceptional products and services.

This synergy between our dedicated workforce and robust support network solidifies reliability, innovation, and excellence in the industry.

Joe Wang, COO

Our company has a stable and reliable supply chain, and we maintain good cooperative relations with many domestic and international first-class manufacturers. We can provide top quality raw materials and equipment in the shortest possible time to

meet the requirements of equipment manufacturing and EPC projects.

Fubin Yang, Head of Procurement

Focus on sustaining Oschatz Global’s unique technical edge in relevant fields, consistently

exploring new avenues to drive the company forward.

Qu Guobin, CTO

Today's quality shapes tomorrow's market. Quality is the key to improving enterprise efficiency and remains the

perpetual focus of any successful business.

Leo Wang, Quality Control Manager